Concretely, we support you with the right technologies

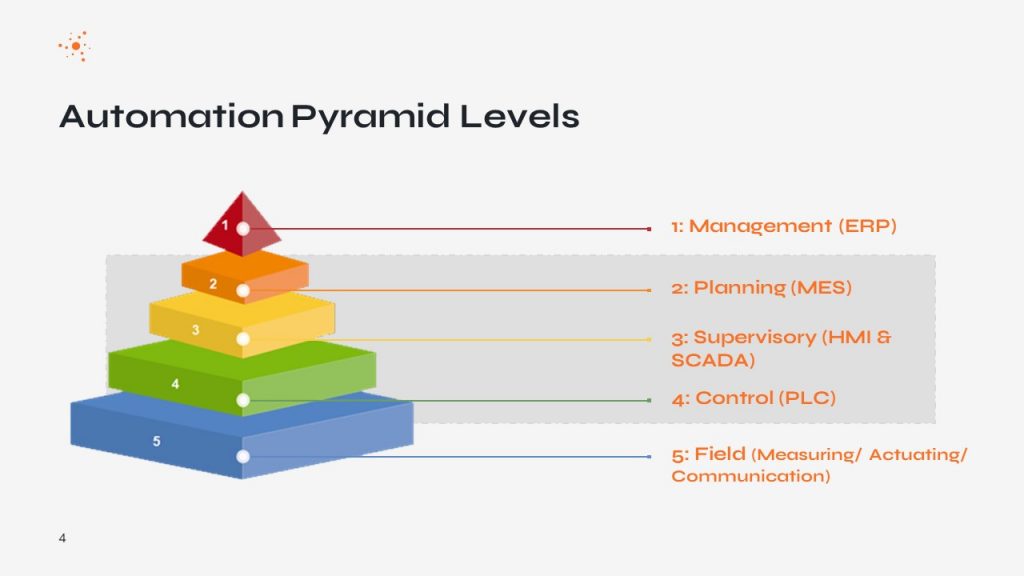

Smart Automation is a combination of deep understanding of the physical process and robust data to allow efficient, accurate and controlled decisions to be made. We are here to help you at every layer to get to this stage. From the bottom layer which is the physical process to the upper layer.

- MES: In the digital age, Manufacturing Execution Systems (MES) are critical components of your manufacturing. Many of you recognize the importance of MES and have begun initiatives as part of your Industry 4.0 strategy, but the majority of manufacturers do not have one in place and operational, and many have not even begun tangible operations. MES projects may get complicated. Otofacto walks you through the technology evaluation, architectural design, implementation, going live, and operations optimization processes.

- Digital Twin: The digital twin is a very powerful concept to model and exchange information about physical objects. Interpreting sensor data in many cases is not meaningful without information about internal structures and history of a machine or component bundled in the digital twin. It is a key building block for an Industry 4.0 framework and a prerequisite for efficient and effective application of intelligent analyses. Designing and implementing digital twins is a key competency of Otofacto.

- Innovative Sensors & Actuators: The long lifetime of machines and the abundance of legacy equipment are a major reason for the slow progress on the Industry 4.0 journey. Our engineers help you to supply your production and products with the right sensors – as add-on or integrated components – that allow you to collect more information for analytics and monitoring tools. For new product development we propose measures for readiness for Industry 4.0 by adding future-proof sensory and actuatory components.

- Edge Computing: Many meaningful activities can be implemented on the edge without the need for a large central infrastructure or a master plan for Industry 4.0. Our software and analytics engineers bring even apparently complex tasks like predictive analytics and artificial intelligence to the edge so that smart local solutions can be found.

- Industrial IoT & Connectivity: A global infrastructure for Industry 4.0 doesn’t appear from nowhere. It requires a scaffold of standards, guidelines, and technology components that a network can grow along over time. The core principles and tools for connectivity are a key part of that scaffold. They can be setup with comparably small effort. Otofacto experts will give you guidance and practical hands-on support in that task.