9 Common Challenges when implementing Operational Technology (OT) Systems

How to kickstart your Digital Transformation Journey implementing Industrial Data Analytics?

TABLE OF CONTENTS

“One of the main challenges for many firms is the “inability to bring everyone together”.

ENGINEERS – IT – MANAGEMENT

Due to that, firms are unable to construct a solution-oriented and results-driven approach to their problems.

Another challenge is the struggle to reduce scrap and increase product quality in complex manufacturing, but also to know how to generate more insights into bottlenecks and dependencies of your production.

You may also encounter some challenges around your data and system integration. For example, when you:

For example, many companies’ level of analysis (and following their potential in data analytics) is limited due to the lack of data contextualization, having no unified tool for extraction, management, storage and no integration of findings into operational business.

Management and organization can also turn out to be a challenge for manufacturing companies due to factors such as:

Overall, digitalization and digitalization transformation journeys demand much more than simple introductions to various technologies into the process. From the many years of experience we have acquired, we can certainly say that many firms tend to overlook this aspect.

Our Industrial Analytics Team (IAT) is a team of IT specialists with a background in Data Science who deliver end-to-end solutions and pave the way towards data-driven decision-making.

Want to tackle the IT based challenges? Check out what we do.

Or looking for solutions on the operational side? Check out our DCT team

TOGETHER…

In short:

They can bring holistic data strategies and experienced technical implementers in the machine room at the same time.

Their goal here is to connect digital programs and daily actions. They can provide you with a flexible service and tailor-made mentality. These notions are key factors in your implementation process to achieve digital maturity and make the most out of it.

Moreover, The focus of this Industrial Analytics Team is based on business added value and measurable project success.

The IAT enables you to use the right tools and ways of working to create an integrated system which allows the clients to view all their operations while bringing together all the data points. Inevitably, allowing a detailed 360° & X-ray view upon all their processes, crucial for an firm beginning their Digital Transformation Journey.

Furthermore, this allows the team to explore major pain points, which can then be turned into points of value!

The strategic dimension encompasses all the other dimensions and lays the foundations for deciding on how to proceed.

In this step, the IAT helps in connecting the end goal of the client with the methodology.

The IAT carefully analyses and constructs a roadmap of the digital transformation journey which is based on all the very specific needs and requirements of the client.

Capture and analysis of the maturity of existing processes for Industry 4.0

Development, operation & support concepts:

The very first step towards digital maturity starts with the IAT taking a deeper look into the client processes. The team analyses the operations, effectiveness of the operations and the level of integration of technology/data in the operations.

Based on this analysis, the team then outlines the initial maturity level of the client.

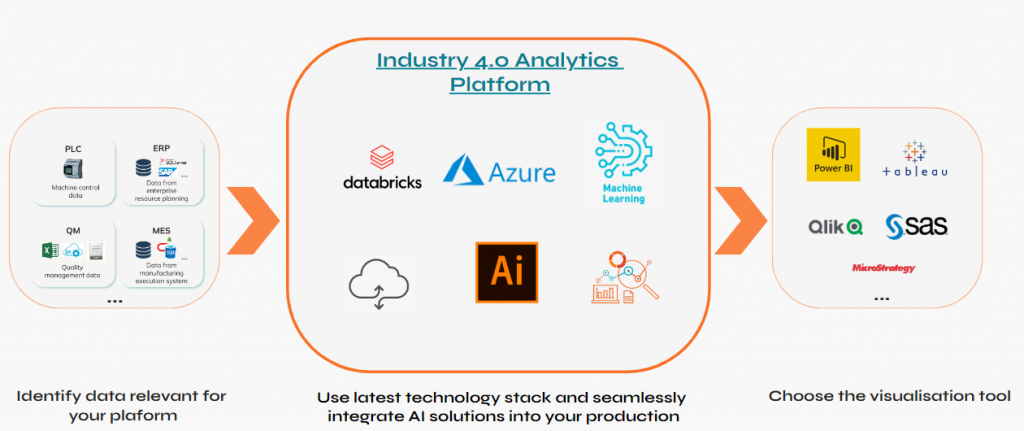

Identification of existing systems

Need for standardization of various data sources in production,

identification & analysis of existing (cloud) infrastructure and data (system),

data quality assessment and definition of data flow (cloud /on-premises) and interfaces

Organization roles and training – Project management

Overall enabling you as a client to be able to setup and run the digitalization process.

Concept development for all phases from proof of concept via piloting to productive system

Every project is new and unique. But IAT has many years of experience, where each project’s detailed process is carefully crafted and stored to be used at a future date. We make use of this file to build with future clients. This allows us to develop a solid result-driven roadmap.

As discussed, one of the many problems faced by our clients is the lack of connection between shopfloor engineers and analysts.

Therefore, based on our experience, we have developed these teams.

More importantly, we have carefully crafted a strong relationship between the two teams such that the partnership allows our clients to gain fruitful benefits and results and not just plain insights in their ambitious Digital transformation Journey.

Our clients can experience difficulties such as:

That’s why collaboration between our two teams exists.

On the one hand, the IAT is a team of experienced and specialized Data Scientists. On the other hand, the Digital Core Team builds the digital transformation strategy roadmap for manufacturing companies, with a focus on the engineering side. Hence, as a whole, both the teams allows clients to boost their operationality and lay the path for digital transformation journey.

Our clients can get several advantages from the Industrial Analytics Team.

One of our clients is a German-Swiss multinational equipment manufacturer that produces, among others, mining trucks. It was quintessential that the trucks were at the top of their class as any breakdown would result in disruption to the mine fields.

Our client was looking for ways to identify the causes of failures and be able to prevent them. This is exactly where we come into the picture.

We used a RaaS (Result-as-a-Service) approach: our client provided us with its data:

Then we integrated it directly into our own SAS-based analytics platform!

Our approach was to identify unusual events that took place right before a truck failed. We have thus:

It turned out that two-thirds of the breakdowns were simply due to drivers pushing the gas pedal with the handbrake on at the same time.

Integration of Machine learning by the client due to the cooperation and interaction of the IAT team. Undoubtedly, improving the digitalization process of the client.

The insight attained was due to the link between different systems. This “link” is one of the most crucial aspects of the IAT team, as motioned above in the text. Moreover, it would have been impossible to come to the insight all alone.

Overall, a massive ROI in terms of improved profitability was realized through this partnership.

Miele is a German manufacturer of high-end domestic appliances and commercial equipment.

Our client was looking to:

Based on the needs of the client we recommended an appropriate infrastructure solution.

We also integrated the IoT hub in MS Azure into the existing on-site infrastructure.

Real-time analysis to detect anomalies in the process.

30% reduction in costs!

The client at the end can derive an actionable and concrete solution, entirely based on the analysis and insights gained from the data collected and the engineers from the shop floors.

This allows our clients to massively improve their production quality, improve maintenance (enable predictive maintenance- ability to detect failure earlier on) and improve production planning.

Eager to start your Digital Transformation Journey?