9 Common Challenges when implementing Operational Technology (OT) Systems

In today’s rapidly evolving technological landscape, Smart Automation stands out as a key driver of efficiency and productivity.

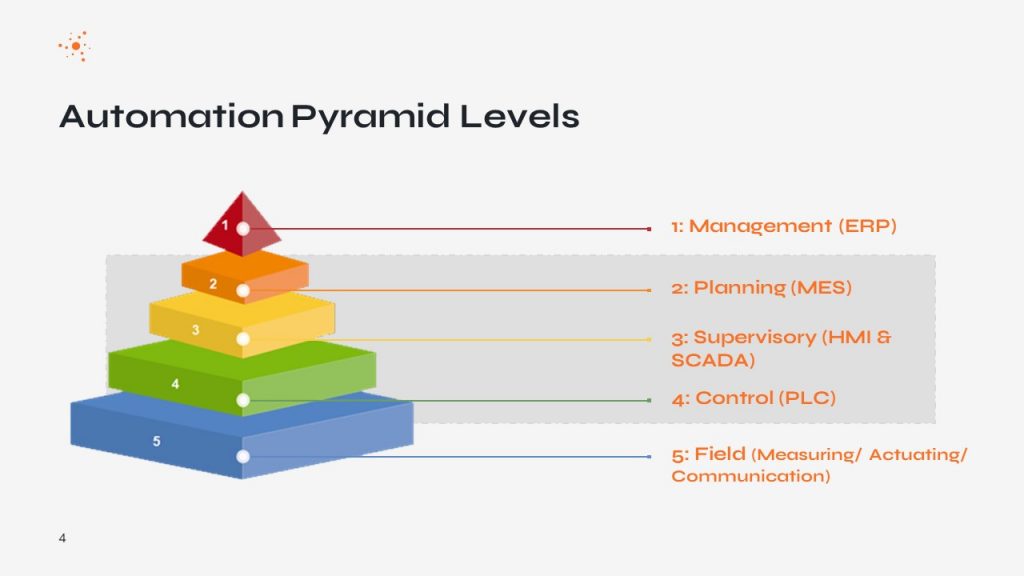

At the heart of this revolution is the Automation Pyramid, a structured representation of the different levels of automation in an industrial setting.

The Automation Pyramid is a hierarchical representation of the various automation levels in an industrial process. It comprises five distinct levels:

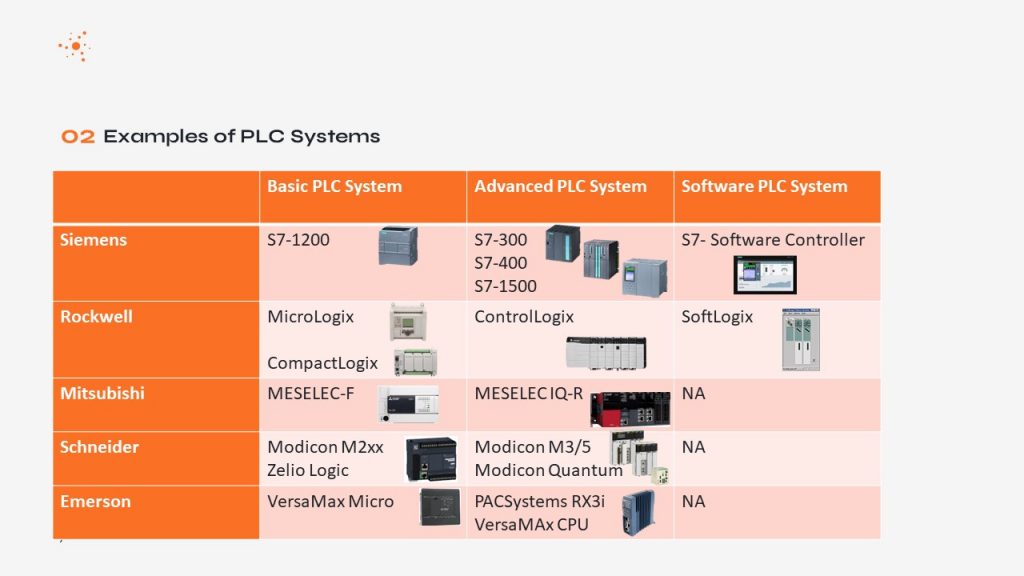

The PLC is an industrial computer designed specifically for controlling manufacturing processes. It connects to field equipment through I/O modules and communicates with other devices or systems using various protocols.

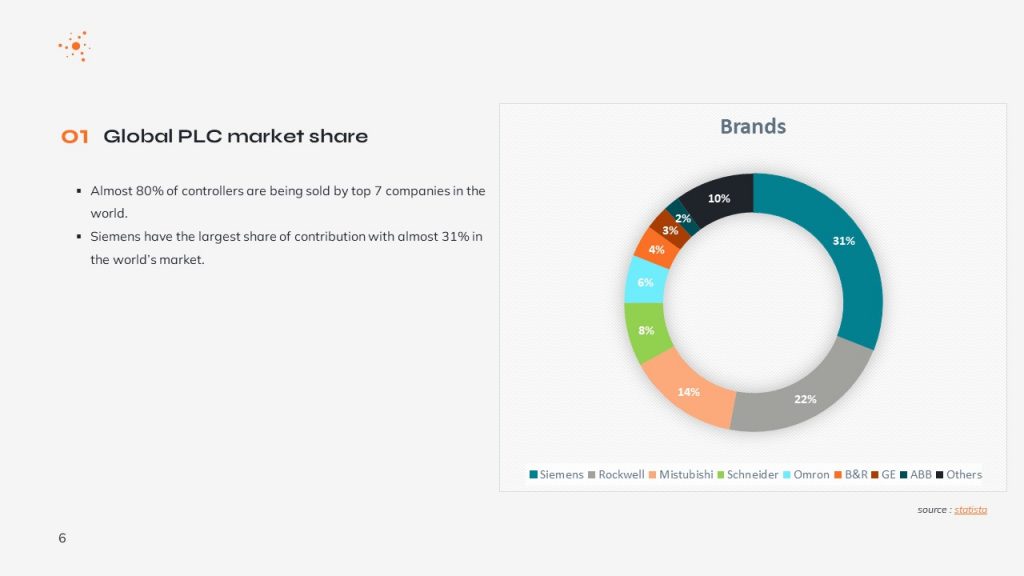

Interestingly, the global PLC market is dominated by a few major players.

Almost 80% of controllers are sold by the top seven companies globally, with Siemens leading the pack, boasting a 31% market share.

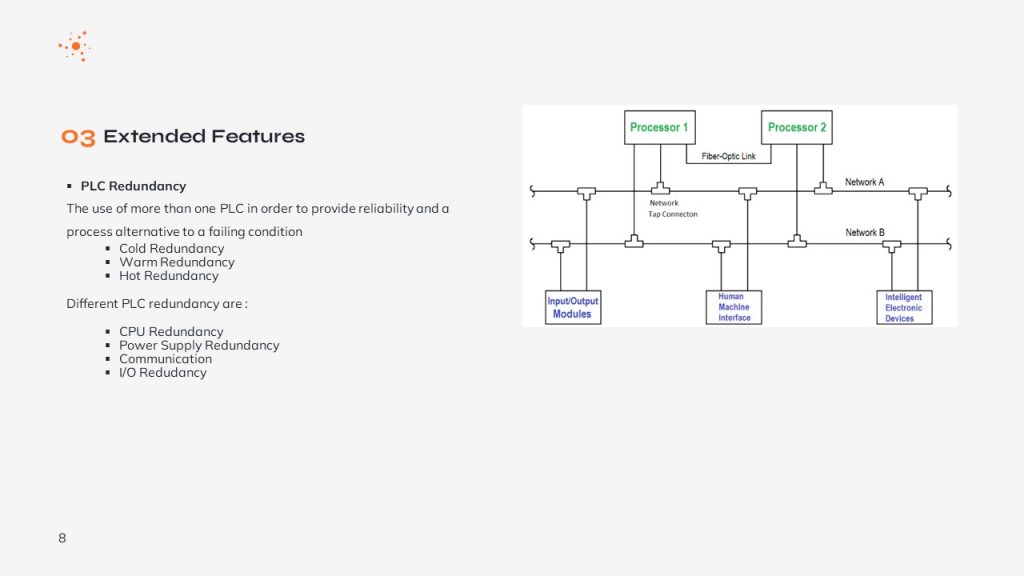

PLCs come with extended features like:

SCADA (Supervisory Control and Data Acquisition) is used for real-time data collection from remote locations and is ideal for displaying large-scale process data. On the other hand, HMIs (Human-Machine Interfaces) are supervisory systems used to monitor local machines. They can be computer-based or panel-based.

Popular SCADA systems include:

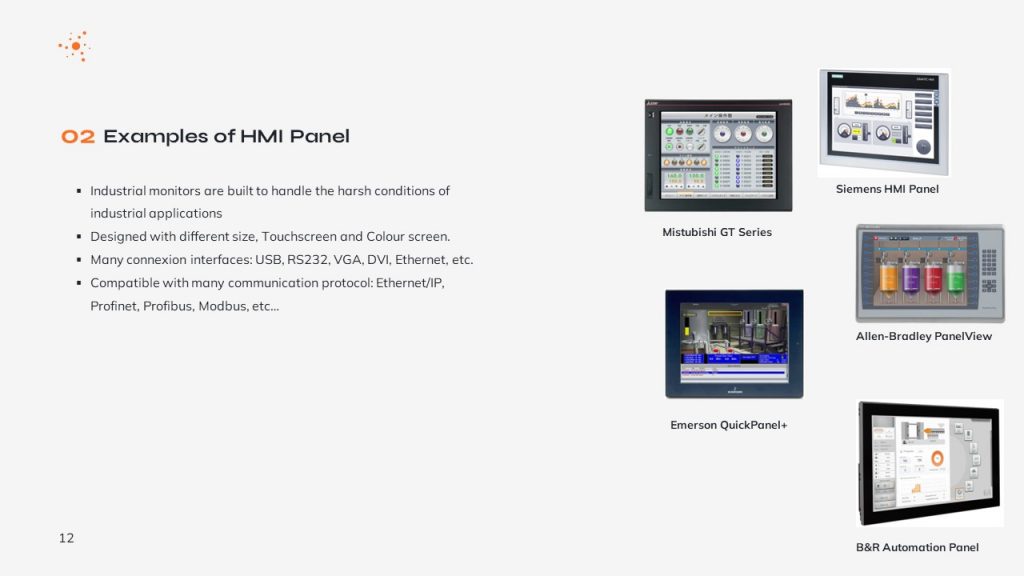

HMIs, especially industrial monitors, are designed to withstand harsh conditions.

They come in various sizes and interfaces, compatible with many communication protocols.

MES software plays a crucial role in optimizing production processes by providing real-time data on equipment utilization and material levels. It can track products throughout the manufacturing process, ensuring any issues are addressed promptly. Furthermore, MES offers valuable insights that can enhance efficiency and reduce costs.

Notable MES systems include:

In conclusion, smart automation technologies, as represented by the Automation Pyramid, are revolutionizing the industrial sector. By understanding and leveraging these technologies, industries can achieve unparalleled efficiency and productivity.

Otofacto provides adapted solutions in order to ensure an added value for its clients by enhancing production performance, maintaining the security of the industrial facilities, reducing the costs, times, risks and working in an eco-friendly environment.

Our Automation Consultants help customers implement process automation systems.